3D printing materials: What is PEEK?

Production and Characteristics of PEEK

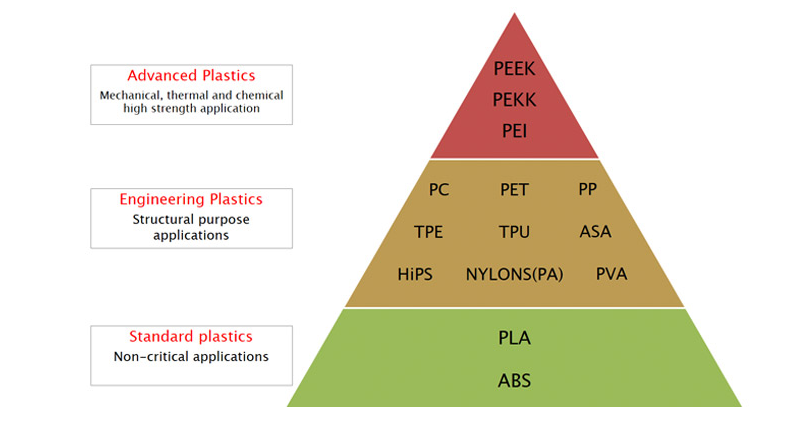

PEEK is a member of the PAEK (polyaryletherketone) family, which is known for its high thermomechanical properties. If we look at the pyramid of different polymers in the industry, PEEK is at the top of the pyramid, in the category of high-performance polymers. Its molecular structure is composed of a ketone and two ethers, organic compounds of the carbonyl family, with a double bond between a carbon and an oxygen atom. It was first marketed at the end of the 1970s, and quickly adopted by sectors such as aeronautics or electronics because of the performance it can offer. If we look at its structure, note that it is a semi-crystalline polymer, therefore when it melts, its molecules arrange themselves under the effect of heat, creating a certain order until the material solidifies completely. This enables it to maintain its mechanical characteristics when the temperature is increased. While this semi-crystalline structure has many advantages, it should be noted that in additive manufacturing, it involves a more complex printing process: it is a highly technical material that requires experience and the appropriate system.

3D Printing With PEEK

In 3D printing, the crystallization process of PEEK must be controlled as part of the material will crystallize, thus changing the density of the material. Therefore, high temperature levels – extrusion, build plate and chamber – must be maintained and fluctuations in temperature need to be avoided. To print 3D print PEEK, you will therefore need a 3D printer with an extruder that can reach 400°C, a chamber that can be heated to 120°C, and a build plate that can heat to 230°C to ensure proper part release at the ending and prevent warping. In terms of chemical reaction, the material changes density during printing, then contracts as it cools.

Though PEEK is a demanding material, it must also be said that it offers very interesting mechanical and chemical characteristics for different industries. In fact, it is very resistant to heat and wear, has a high chemical resistance, it’s sterilizable and has dielectric properties. PEEK also has a high strength-to-weight ratio and is often used to replace certain metals. Finally, PEEK is flame resistant which makes it an interesting 3D printing material for sectors such as aerospace that have high fire/smoke constraints. If we were to compare it with other high-performance thermoplastics, PEEK outstrips ULTEM in mechanical strength.

Applications

This high-performance material is particularly interesting for the medical sector. Since it’s sterilizable and biocompatible, it can be used for a number of applications including the manufacture of custom-made implants. In fact, PEEK has properties similar to human bone: an implant 3D printed with PEEK could therefore promote the reconstruction of tissues around the implant, accelerating osseointegration. As such, a number of companies have turned to 3D printing of PEEK to design customized medical devices.

Aerospace and automotive are also markets where PEEK 3D printing is common. Additive manufacturing allows for the creation of high-performance, lightweight, custom and on-demand parts: coupled with the use of a high-performance material, it is even more attractive. PEEK will offer greater wear and temperature resistance, while optimizing weight – a key factor in such areas. It is so capable in fact that parts from PEEK have already been sent to space, further proof that this material can meet the needs of even the most demanding sectors.