Chemical resistance of 3D printing materials

Chemical resistance of 3D printing materials

With growing interest in 3D printing, there are new materials coming to market – and with them new means and opportunities for using 3D printers. It’s common for prints to be used in outside conditions where they need to withstand wind and rain, UV light – or in industry – withstand harsh mechanical stress. Often prints are exposed to various chemicals.

That is why we have decided to explore the chemical resistance of printing materials in detail. We’ll show you chemically resistant polymers and you’ll learn how exposure to chemicals affects material durability.

Prusament PLA, PVB, PETG, ASA and PC-Blend were exposed by various chemical substances: We chose those which are common and safe to work with.

We believe that our tests will help you choose the right material fitted for your needs.

Chemical resistance of commonly used 3D printing materials

In general, engineering materials are the most resistant to chemicals: Those with excellent chemical resistance include PP (polypropylene), PA (polyamide, nylon), PE (polyethylene), PEEK (polyetheretherketone), PTFE (polytetrafluoroethylene, Teflon), PVC (polyvinyl chloride), or PVDF (polyvinylidene fluoride).

Materials with good chemical resistance include PC (polycarbonate), TPU, PETG, ASA, or ABS. However, the resistance of these materials depends on the specific environment, the ambient temperature and other types of stresses. For example, ABS material degrades very quickly in acetone.

Materials that do not have technical characteristics – such as PLA, PVB – are not suitable for use in chemically aggressive environments – acids, alcohols, etc.

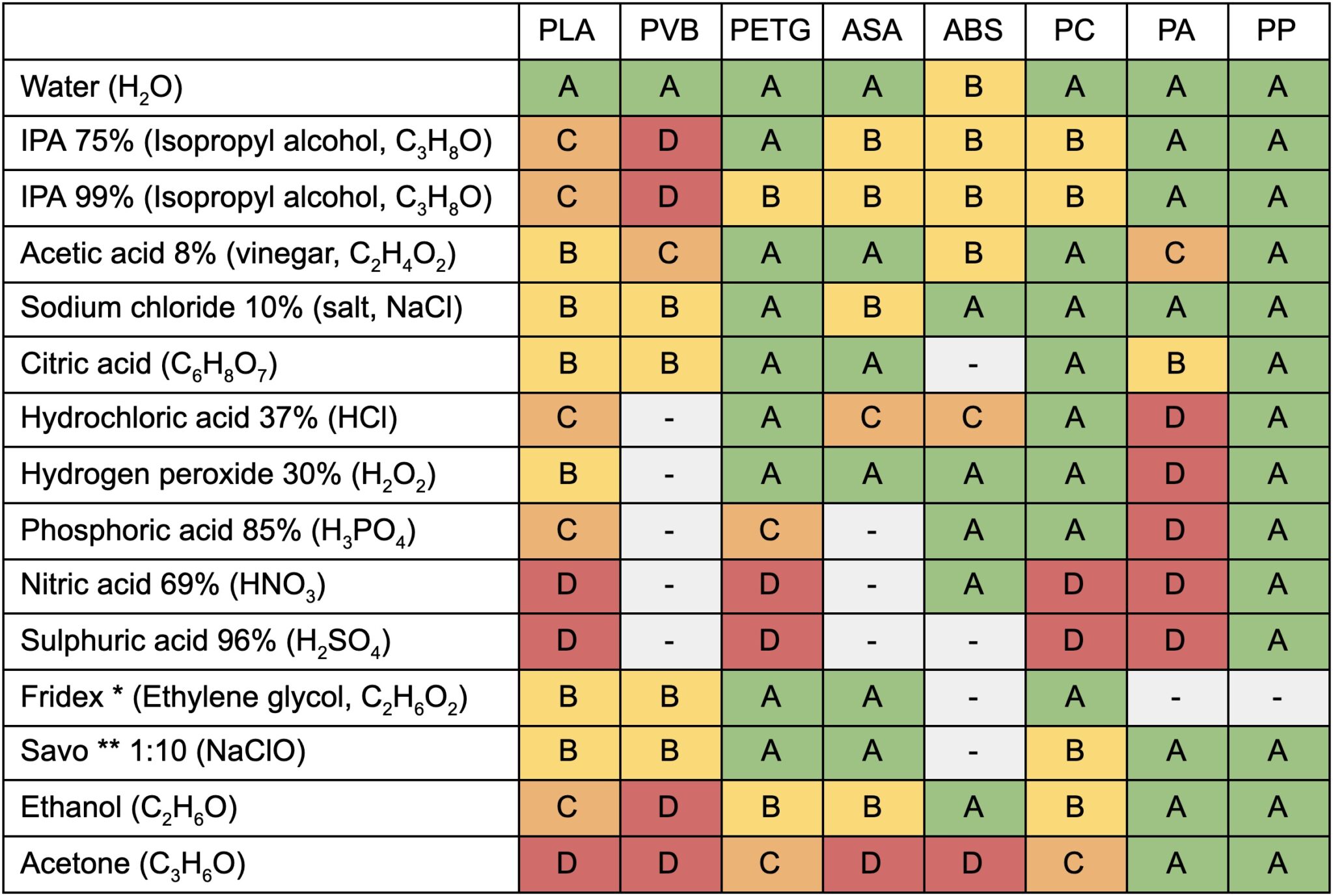

Below is an indicative table of the most commonly used polymers for 3D printing that have been tested in various chemicals. According to the resistance rating from A to D, it can be determined which polymer is suitable for use in a given substance. The tests were carried out at 23 °C.

Rating:

A – Resists very well. Polymer does not melt, absorb substance, or swell during a week’s immersion (less than 1% change in weight and dimensions).

B – Resists moderately to well. Slight swelling or change in weight (2 – 3% change in weight or dimensions).

C – Resists poorly. Significant swelling and change in weight of the test sample (4-5% change in weight or dimensions) occurs with prolonged exposure of the polymer.

D – Does not resist. A red colour indicates a significant change in weight, severe swelling (change in weight or dimensions over 5%) or complete destruction of the fibre

From the measurement results, we can compare how the impact of the chemical affects the strength and toughness of the material.

Of the materials tested, PC Blend clearly stands out as the toughest material even after detailed testing.